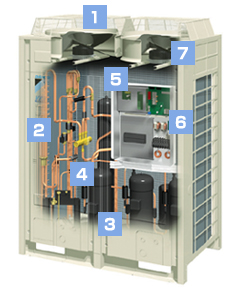

VRV III Heat Recovery (REYQ)

Daikin’s constant efforts have been devoted towards using the latest and most revolutionary technologies in the

development of the VRV III system for large-sized buildings. The system offers larger outdoor capacities, greater

energy savings, easier installation, longer actual and total piping, and more.

1. Newly improved fans and grilles

A higher external static pressure has been achieved-from 0.24” to 0.32” W.G.-thanks to reduced internal pressure loss, use of the new fans and the new grilles.

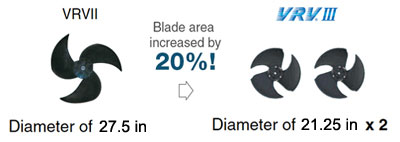

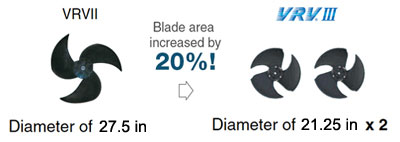

New aero spiral fan and aero asymmetrical fan

The area of these new fan blades has been increased and optimised for each casing. This greatly reduces pressure loss, resulting in a higher external static pressure.

New aero spiral fan (Powerful Dual DC fan)

In the 12-Ton unit, a single fan with a diameter of 27.5" has been split into two fans with diameters of 21.25" each. Blade area has been increased by 20% to increase airflow.

Aero smooth grille

The three-dimensional, integrated, soft woven steel grilles are covered with a plastic coating that protects them from rotating elements and the possibility of fire damage.

2. Heat exchanger

The new heat exchanger contributes to a higher COP because of an increase from 7% to 10% of the effective length as well as an optimised e-Pass heat exchanger.

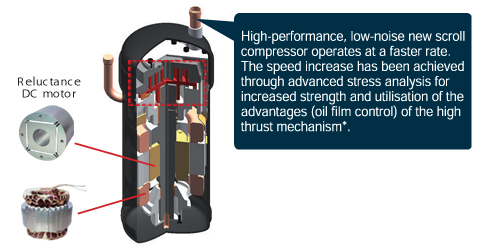

3. Improving the high efficiency compressor to achieve a higher COP and larger capacity

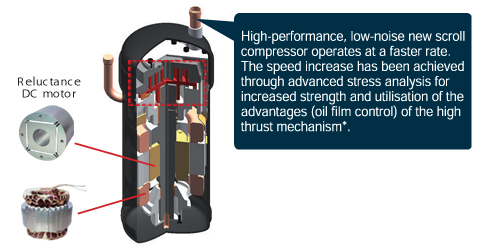

Reluctance DC scroll compressor

Daikin's unique scroll compressor minimises heat loss, and is driven by a high efficiency motor to achieve significant Energy savings.

* High thrust mechanism:

By introducing high pressure oil, the reactive force from the fixed scroll is added to the internal force, thereby reducing thrust losses. This results in improved efficiency and suppressed sound levels.

4. Heat transfer circuit

By performing sub cooling before the expansion process, the volume of refrigerant that needs to be circulated to the indoor units can be reduced without lowering the evaporation temperature. This permits the use of narrower piping.

5. Compact aero box

Realises a compact casing by stacking the Inverter and control PCBs plus optimising the internal design to suit airflow speed. This achieves lower noise and reduces the power required by the large-diameter fanned outdoor unit.

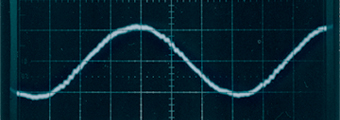

6. Smooth sine wave DC Inverter

By adoption of the Sine Wave, which smoothes the rotation of the motor, operation efficiency is improved sharply.

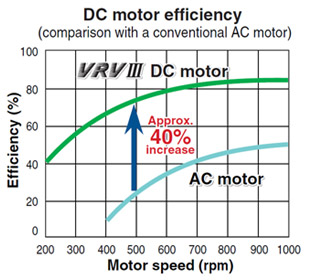

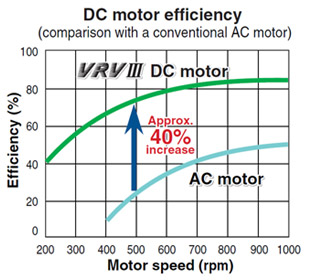

7. DC fan motor

Across entire range of models (from 6 to 28-Ton).

Efficiency improvement by up to 40% especially at low speed.

Note: Data are based on studies conducted under controlled conditions at a Daikin laboratory.